Filter press 200 type

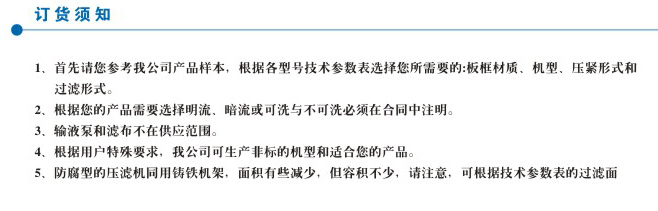

Model | 过 | 滤 | 滤 | 滤 | 容 | 过 | 地脚中心 | 外形尺寸mm | 质 量 | 备 注 | |||

长L1 | 宽B | 长 | 宽 | 高 | |||||||||

B MSAQS0.5/200 -20 | 0.5 | 200 | 20 | 9 | 5 | 0.6 | 630 | 220 | 950 | 450 | 500 | 180 | 有不锈 |

The plate and frame filter press has three forms: manual compression, mechanical compression and hydraulic compression. Manual compression is a screw jack pushing the compression plate to compress; mechanical compression is a motor with H-type reduction box, which is pressed by the frame transmission part to push the compression plate; hydraulic compression is a hydraulic station with a hydraulic cylinder on the frame The component pushes the compression plate to compress it. Two beams connect the thrust plate and the pressing device together to form a frame. The pressing plate on the frame is connected with the pressing device. Between the thrust plate and the pressing plate, filter plates and filter frames are alternately arranged in turn. The filter medium is sandwiched between the filter plate and the filter frame; the pressing device pushes the pressing plate to compress all the filter plates and the filter frame in the frame, and the filter can be carried out after the rated pressing force is reached. The suspension enters each filter chamber from the feed hole on the thrust plate (the filter frame and the adjacent filter plate constitute the filter chamber), the solid particles are trapped in the filter chamber by the filter medium, and the filtrate penetrates the medium and is discharged from the outlet hole. outside.

The output of the plate and frame filter press has two forms: open flow and undercurrent. The filtrate is directly discharged from the outlet hole of each filter plate to the outside of the machine. The open flow type is convenient to monitor the filtration condition of each filter plate. If the filtrate of a certain filter plate is not pure, you can close the outlet of the plate; if the filtrate of each filter plate is combined and discharged out of the machine through a liquid outlet pipe, it is called the underflow type. The underflow type is used for the filtrate to be volatile or harmful to the human body. Filtration of the suspension.

板框压滤机有手动压紧、机械压紧和液压压紧三种形式。手动压紧是螺旋千斤顶推动压紧板压紧;机械压紧是电动机配H型减速箱,经机架传动部件推动压紧板压紧;液压压紧是有液压站经机架上的液压缸部件推动压紧板压紧。两横梁把止推板和压紧装置连在一起构成机架,机架上压紧板与压紧装置饺接,在止推板和压紧板之间依次交替排列着滤板和滤框,滤板和滤框之间夹着过滤介质;压紧装置推动压紧板,将所有滤板和滤框压紧在机架中,达到额定压紧力后,即可进行过滤。悬浮液从止推板上的进料孔进入各滤室(滤框与相邻滤板构成滤室),固体颗粒被过滤介质截留在滤室内,滤液则透过介质,由出液孔排出机外。

板框压滤机的出液有明流和暗流两种形式,滤液从每块滤板的出液孔直接排出机外的称明流式,明流式便于监视每块滤板的过滤情况,发现某滤板滤液不纯,即可关闭该板出液口;若各块滤板的滤液汇合从一条出液管道排出机外的则称暗流式,暗流式用于滤液易挥发或滤液对人体有害的悬浮液的过滤。